Applications of Ferro Vanadium in the Automotive and Energy Sectors

Applications of Ferro Vanadium in the Automotive and Energy Sectors

In an era where industries are evolving towards greater efficiency, strength, and sustainability, Ferro Vanadium (FeV) has emerged as a key alloying element driving innovation. Its exceptional ability to enhance the strength, hardness, and corrosion resistance of steel makes it indispensable, especially in the automotive and energy sectors — two industries where performance, safety, and durability are paramount.

Let’s explore how Ferro Vanadium contributes to building stronger vehicles, more reliable infrastructure, and a more efficient energy future.

The Role of Ferro Vanadium in Modern Industries

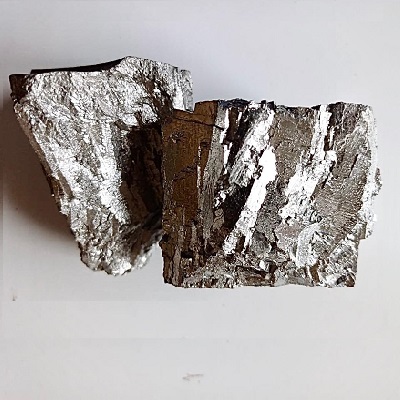

Ferro Vanadium

Ferro Vanadium is an iron-vanadium alloy primarily used as an additive in steelmaking. Even in small quantities, vanadium can significantly improve steel’s mechanical properties — making it stronger, lighter, and more resistant to wear and fatigue.

In industries that demand both performance and longevity, such as automotive manufacturing and energy production, these improvements make a world of difference.

Ferro Vanadium in the Automotive Sector

Ferro Vanadium

The automotive industry is under constant pressure to produce lighter, stronger, and more fuel-efficient vehicles without compromising safety or durability. Ferro Vanadium plays a crucial role in achieving this balance.

1. High-Strength, Low-Alloy (HSLA) Steels

Vanadium is widely used in the production of HSLA steels, which are lightweight yet incredibly strong. These steels are essential in manufacturing chassis, suspension systems, body frames, and reinforcements, allowing vehicles to reduce weight while maintaining structural integrity.

A lighter vehicle means better fuel efficiency and lower emissions, helping automakers meet environmental standards while keeping performance high.

2. Improved Fatigue Resistance

Automotive components such as engine parts, crankshafts, gears, and axles endure repetitive stress and high rotational speeds. Ferro Vanadium enhances steel’s fatigue strength, ensuring that these components can handle continuous motion and mechanical vibrations without cracking or deforming over time.

3. Enhanced Safety and Impact Strength

In the event of a collision, the ability of steel to absorb energy without breaking is critical. Vanadium strengthens the steel’s impact resistance, ensuring passenger safety while allowing manufacturers to use thinner and lighter materials without compromising protection.

4. Wear and Heat Resistance in Engine Components

Engine environments generate immense heat and friction. The addition of Ferro Vanadium helps create steels that resist thermal degradation and wear, extending the lifespan of pistons, valves, and other engine components. This translates to more efficient engines and reduced maintenance costs.

Ferro Vanadium in the Energy Sector

Ferro Vanadium

The energy industry — from traditional power generation to renewable technologies — relies on materials that can handle high temperatures, pressure, and corrosion. Ferro Vanadium’s ability to enhance the stability and strength of steel makes it a valuable asset in this field.

1. Power Plants and Turbines

In thermal and hydroelectric power plants, vanadium-alloyed steels are used in boilers, turbines, and pressure vessels. These components must endure high stress and temperature cycles. Ferro Vanadium ensures the steel retains its strength and creep resistance, preventing structural failure and improving plant efficiency.

2. Oil and Gas Exploration

Drilling rigs, pipelines, and offshore platforms are constantly exposed to harsh environments — from deep-sea pressures to corrosive fluids. Ferro Vanadium enhances steel’s corrosion resistance and toughness, ensuring long-lasting performance in extreme conditions.

3. Renewable Energy Infrastructure

With the global shift toward renewable energy, vanadium has found new importance in wind turbine components and solar energy systems. Vanadium-alloyed steels are used in wind turbine shafts and towers, offering exceptional strength and fatigue resistance under dynamic wind loads.

Beyond steelmaking, vanadium compounds are also vital in developing vanadium redox flow batteries (VRFBs) — large-scale energy storage systems that store electricity from renewable sources. These batteries provide stable and long-lasting energy storage, making renewable energy more reliable and efficient.

4. Energy Pipelines and Transmission

In the energy transport sector, where steel pipelines carry oil, gas, and hydrogen, Ferro Vanadium helps improve ductility and resistance to cracking, ensuring the safe and efficient movement of energy resources across vast networks.

Why Ferro Vanadium is Indispensable

Ferro Vanadium

Across both automotive and energy sectors, Ferro Vanadium stands out because it offers a rare combination of benefits:

- Higher tensile and yield strength

- Improved resistance to wear, corrosion, and fatigue

- Enhanced thermal stability and creep resistance

- Better weldability and structural uniformity

These characteristics make it not just an additive, but a performance enabler — helping manufacturers design materials that meet the increasing demands of modern technology and sustainability.

The Future of Ferro Vanadium

As industries push towards lighter, more efficient, and environmentally sustainable solutions, the role of Ferro Vanadium is only set to expand. From electric vehicle components to renewable energy systems, its ability to strengthen and stabilize steel will remain central to innovation.

Ongoing research is also exploring how Ferro Vanadium can contribute to hydrogen storage technologies and next-generation energy grids, opening new pathways for growth and efficiency.

FAQs about Ferro Vanadium

- What is the main benefit of using Ferro Vanadium in steel?

It significantly improves strength, toughness, and resistance to wear and corrosion, even in small quantities. - Why is Ferro Vanadium important in the automotive industry?

It allows for the production of high-strength, lightweight steels that improve vehicle performance, safety, and fuel efficiency. - How does Ferro Vanadium help the energy sector?

It strengthens materials used in turbines, pipelines, and renewable systems, enabling them to handle high stress, heat, and corrosion. - Is Ferro Vanadium environmentally friendly?

Yes, it helps reduce material weight and energy consumption in manufacturing, supporting sustainable industrial practices. - What industries commonly use Ferro Vanadium?

Besides automotive and energy, it’s also used in aerospace, construction, and tool manufacturing for high-performance applications.

Power Your Industry with DSalloyd Pvt. Ltd

At DSalloyd Pvt. Ltd, we take pride in delivering high-quality Ferro Vanadium and Noble Alloys that meet the rigorous demands of modern industry. Our materials are engineered for consistency, purity, and superior performance, helping manufacturers produce stronger steels and more reliable products.

Whether you’re in the automotive, energy, or metallurgical sector, DSalloyd Pvt. Ltd is your trusted partner for excellence in alloy solutions.

Strengthen your materials — and your future.

Visit www.dsalloyd.com to explore our product range or connect with our experts today.